VDA239-100

VDA 239-100 Material specification

Mild steels are characterized by low yield strength and high ductility and are especially suited for the production of complex parts. They are produced as aluminum killed non-IF grades or as IF grades. Soft IF grades have an excellent formability and show very low carbon and nitrogen contents and are stabilized by the addition of titanium and/or niobium.

Material:

CR1/2/3/4/5, HR2, CR210/240/270/300/340/380/420LA, HR300/340/420/460/500LA,HR300/340/420/460/500MC, CR160/180/210/240IF, CR180/210/240BH, CR290Y490T/330Y590T/440Y780T/590Y980T/700Y980T-DP, HR330Y580T-DP, CR400Y690T/450Y780T-TR

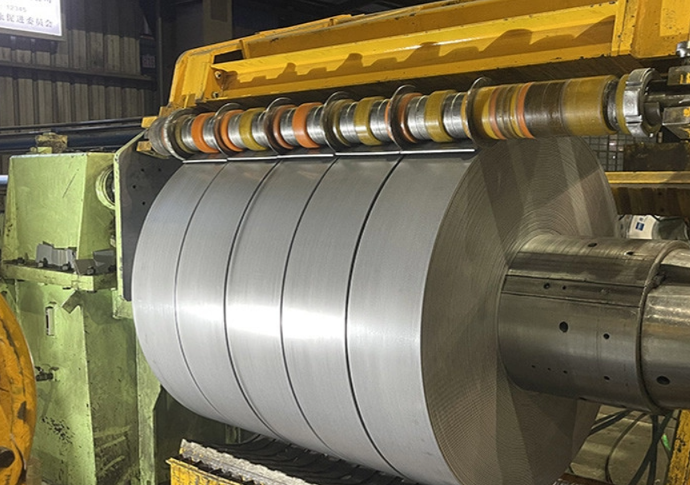

Application: Uncoated and continuously coated, surface treated, cold rolled and hot rolled sheet steel materials

Thickness: 0.5~6.0mm

Width: Customer's Requirement

Type: Coil, Sheet, Plate

Tolerance:

Min Width Tolerance ±0.1

|

Stahlgüte /

Steel Grade |

Streckgrenze /

Yield Strength Rp0,2 |

Zugfestigkeit /

Tensile Strength Rm |

Bruchdehnung /

Elongation |

r90

|

n

|

|||

|

MPa

|

MPa

|

A %

|

A 50mm %

|

A 80mm %

|

r90/20

|

rm/20

|

n10-20/Ag

|

|

|

Kaltgewalzt / Cold Rolled

|

||||||||

|

CR1

|

140-300

|

270-410

|

- |

≥30

|

≥28

|

- | - | - |

|

CR2

|

140-240

|

270-370

|

- |

≥34

|

≥34

|

≥1,3

|

≥1,2

|

≥0,16

|

|

CR3

|

140-210

|

270-350

|

- |

≥38

|

≥38

|

≥1,8

|

≥1,5

|

≥0,18

|

|

CR4

|

140-180

|

270-330

|

- |

≥40

|

≥39

|

≥1,9

|

≥1,6

|

≥0,20

|

|

CR5

|

110-170

|

260-330

|

- |

≥42

|

≥41

|

≥2,1

|

≥1,8

|

≥0,22

|

|

Warmgewalzt / Hot Rolled

|

||||||||

|

HR2

|

180-290

|

270-400

|

≥34

|

≥32

|

≥30

|

- | - |

≥0,16

|

|

Einschränkungen siehe 7.2 / Restrictions see 7.2.

|

||||||||

|

Stahlgüte /

Steel Grade |

Streckgrenze /

Yield Strength Rp0,2 |

Zugfestigkeit /

Tensile Strength Rm |

Bruchdehnung /

Elongation |

r

|

n

|

|||

|

MPa

|

MPa

|

A %

|

A 50mm %

|

A 80mm %

|

r0/20

|

rm/20

|

n10-20/Ag

|

|

|

Kaltgewalzt / Cold Rolled

|

||||||||

|

CR210LA

|

210-300

|

310-410

|

- |

≥31

|

≥29

|

≥1,0

|

≥1,1

|

≥0,15

|

|

CR240LA

|

240-320

|

320-420

|

- |

≥29

|

≥27

|

- | - |

≥0,15

|

|

CR270LA

|

270-350

|

350-450

|

- |

≥27

|

≥25

|

- | - |

≥0,14

|

|

CR300LA

|

300-380

|

370-470

|

- |

≥25

|

≥23

|

- | - |

≥0,14

|

|

CR340LA

|

340-430

|

410-520

|

- |

≥23

|

≥21

|

- | - |

≥0,12

|

|

CR380LA

|

380-470

|

450-560

|

- |

≥21

|

≥19

|

- | - |

≥0,12

|

|

CR420LA

|

420-520

|

480-590

|

- |

≥18

|

≥17

|

- | - |

≥0,11

|

|

Warmgewalzt niedrig- und mikrolegiert / Hot Rolled Low Alloy

|

||||||||

|

HR300LA

|

300-380

|

380-500

|

≥28

|

≥26

|

≥24

|

- | - |

≥0,14

|

| HR340LA | 340-440 | 420-540 | ≥26 | ≥24 | ≥22 | - | - | ≥0,13 |

| HR420LA | 420-520 | 480-600 | ≥23 | ≥21 | ≥19 | - | - | - |

| HR460LA | 460-560 | 520-640 | ≥22 | ≥20 | ≥18 | - | - | - |

| HR500LA | 500-620 | 560-700 | ≥22 | ≥20 | ≥18 | - | - | - |

| Warmgewalzte Feinkornstähle / Hot Rolled Small Grain Size Low Alloyed Steels | ||||||||

| HR300MC | 300-380 | 380-500 | ≥28 | ≥26 | ≥24 | - | - | ≥0,14 |

| HR340MC | 340-440 | 420-540 | ≥26 | ≥24 | ≥22 | - | - | ≥0,13 |

| HR420MC | 420-520 | 480-600 | ≥21 | ≥20 | ≥18 | - | - | - |

| HR460MC | 460-560 | 520-640 | ≥20 | ≥19 | ≥17 | - | - | - |

| HR500MC | 500-620 | 560-700 | ≥17 | ≥19 | ≥14 | - | - | - |

| Einschränkungen siehe 7.2 / Restrictions see 7.2. | ||||||||

|

Stahlgüte /

Steel Grade |

Streckgrenze /

Yield Strength Rp0,2 |

Zugfestigkeit /

Tensile Strength Rm |

Bruchdehnung /

Elongation |

n

|

BH2

|

|||

|

MPa

|

MPa

|

A %

|

A 50mm %

|

A 80mm %

|

n4-6

|

n10-20/Ag

|

MPa

|

|

|

Kaltgewalzte Dualphasenstähle / Cold Rolled Dual Phase Steels

|

||||||||

|

CR290Y490T-DP

|

290-380

|

490-600

|

- |

≥26

|

≥24

|

≥0,19

|

≥0,19

|

≥30

|

|

CR330Y590T-DP

|

330-430

|

590-700

|

- |

≥21

|

≥20

|

≥0,18

|

≥0,14

|

≥30

|

|

CR440Y780T-DP

|

440-550

|

780-900

|

- |

≥15

|

≥14

|

≥0,15

|

≥0,11

|

≥30

|

|

CR590Y980T-DP

|

590-740

|

980-1130

|

- |

≥11

|

≥10

|

- | - |

≥30

|

|

CR700Y980T-DP

|

700-850

|

980-1130

|

- |

≥9

|

≥8

|

- | - |

≥30

|

|

Warmgewalzter Dualphasenstahl / Hot Rolled Dual Phase Steel

|

||||||||

|

HR330Y580T-DP

|

330-450

|

580-680

|

≥23

|

≥21

|

≥19

|

≥0,16

|

≥0,13

|

≥30

|

|

Kaltgewalzte TRIP-Stähle / Cold Rolled TRIP Steels

|

||||||||

|

CR440Y690T-TR

|

400-520

|

690-800

|

- |

≥25

|

≥24

|

- |

≥0,19

|

≥40

|

|

CR450Y780T-TR

|

450-570

|

780-910

|

- |

≥22

|

≥21

|

- |

≥0,16

|

≥40

|

|

Kaltgewalzte Komplexphasenstähle / Cold Rolled Complex Phase Steels

|

||||||||

|

CR570Y780T-CP

|

570-720

|

780-920

|

- |

≥11

|

≥10

|

- | - |

≥30

|

|

CR780Y980T-CP

|

780-950

|

980-1140

|

- |

≥7

|

≥6

|

- | - |

≥30

|

|

Warmgewalzte Komplexphasen- und Martensitphasenstähle /

Hot Rolled Complex Phase and Martensitic Steels |

||||||||

| HR660Y760T-CP | 660-820 | 760-960 | ≥13 | ≥11 | ≥10 | - | - | ≥30 |

| HR900Y1180T-MS | 900-1150 | 1180-1400 | ≥8 | ≥6 | ≥5 | - | - | ≥30 |

|

Warmgewalzte ferritisch-bainitische Stähle / Hot Rolled Ferritic Bainitic Steels

|

||||||||

| HR300Y450T-FB | 300-400 | 450-550 | ≥27 | ≥25 | ≥24 | - | - | ≥30 |

| HR440Y580T-FB | 440-600 | 580-700 | ≥17 | ≥16 | ≥15 | - | - | ≥30 |

| HR600Y780T-FB | 600-760 | 780-920 | ≥15 | ≥13 | ≥12 | - | - | ≥30 |

| Einschränkungen siehe 7.2 / Restrictions see 7.2. | ||||||||

|

Q/BQB

408-2023 |

GB/T

5213-2019 |

EN10130

:2006 |

VDA 239-100

:2016 |

JIS G3141

:2021 |

JFS A2001

:2014 |

ASTM

A1008M-21 |

|

DC01/SPCC/BLC

|

DC01

|

DC01

|

CR1

|

SPCCT

|

JSC270C

|

CS Type C

|

|

DC03/SPCD/BLD

|

DC03

|

DC03

|

CR2

|

SPCD

|

JSC270D

|

CS Type A, B

|

|

DC04/SPCE/BUSD

|

DC04

|

DC04

|

CR3

|

SPCE

|

JSC270E

|

D

S Type A, B

|

|

DC05/SPCF/BUFD

|

DC05

|

DC05

|

CR4

|

SPCF

|

JSC270F

|

DDS

|

|

DC06/SPCG/BSUFD

|

DC06

|

DC06

|

CR4

|

SPCG

|

JSC260G

|

E

DDS

|

|

DC07

|

DC07

|

DC07

|

- | - | - | - |