In recent years, in factories such as elevator factories, high-voltage switches, and high-voltage electric cabinets, because of the components of electric cabinets, a large number of steel plates have entered the production process as raw materials, and the difficulties in production and operation for workers have intensified.

Starting from 2022, more and more customers will call to inquire about solutions for steel plate feeding assisted manipulators.

Today we are going to talk about how this power-assisted manipulator is applied to plate products and how to quickly load materials.

Products used in this issue

Plate loading manipulator

Traditional Feeding

①Manual handling, the steel plate is too heavy and requires the cooperation of multiple people to complete, and it is easy to cause work-related injuries during the handling process;

The weight of the different thickness of the steel plate/aluminum plate

|

Board length /mm

|

Plate width /mm

|

Thickness /mm

|

Weight /kg

|

| 2000 | 1000 | 1 | 15.6 |

| 2000 | 1000 | 2 | 31.2 |

| 2000 | 1000 | 3 | 46.8 |

| 2500 | 1250 | 1 | 24.38 |

| 2500 | 1250 | 2 | 48.75 |

| 2500 | 1250 | 3 | 73.13 |

| 3000 | 1500 | 1 | 35.1 |

| 3000 | 1500 | 2 | 70.2 |

| 3000 | 1500 | 3 | 105.3 |

As can be seen from the data in the chart, any sheet plate is large in size and heavy, and it is difficult to transport and load materials by manpower only. Besides, the edges and corners of the sheet are very sharp, which is easy to cause industrial injury risk.

② electric hoist cantilever crane, the operation is still heavy, and there is no safety protection device;

Figure 1: Electric Hoist Cantilever Crane

Figure 1: Electric Hoist Cantilever Crane

Plate Loading Manipulator

①The number of operators is reduced to 1, the efficiency is increased by 31%, the cost is saved by 43%, and the problem of work-related injuries is avoided;

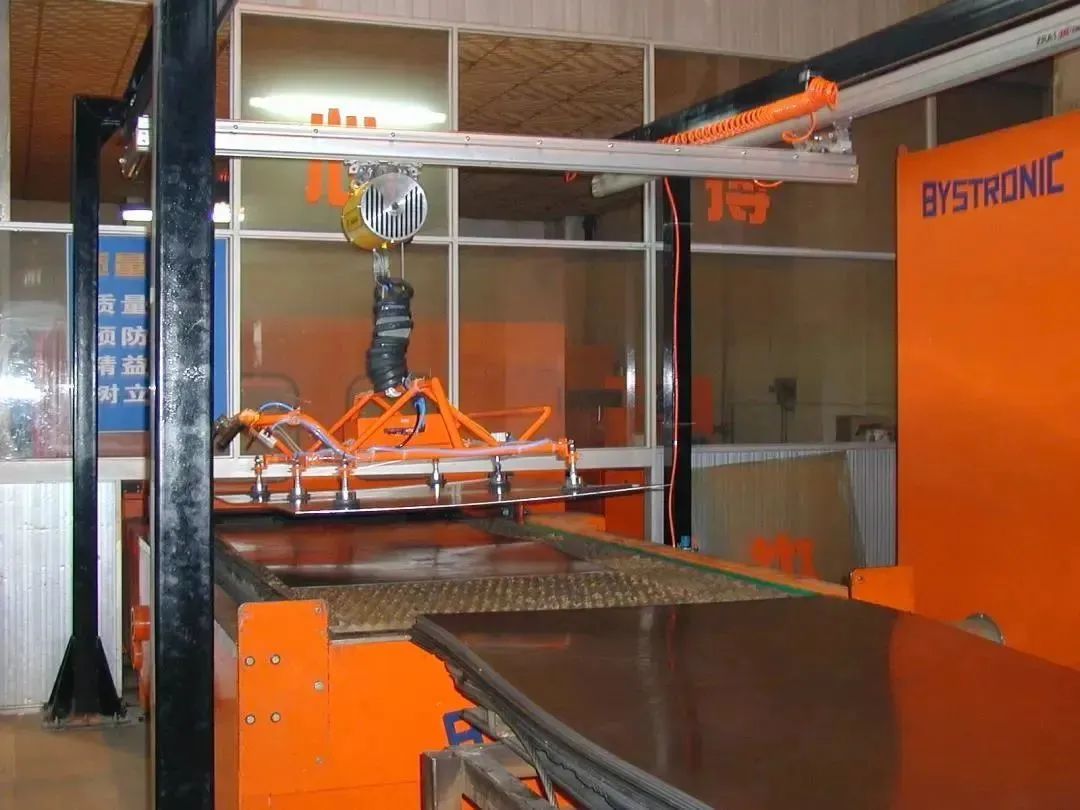

Figure 2: Plate Feeding Machine Hand Material

Figure 2: Plate Feeding Machine Hand Material

②The system consists of three major parts: track system, pneumatic balance crane host and standardized steel plate handling fixture (vacuum adsorption fixture);

Figure 3: Pneumatic Balancing Crane

Figure 3: Pneumatic Balancing Crane

③It is equipped with a load indicator, which can indicate the load status. When the equipment is loaded, the indicator is red. Equipped with misoperation protection function, when the workpiece (that is, the steel plate to be transported) is not effectively supported by the work surface, the unloading button will fail to avoid the risk of industrial injury caused by misoperation;

④Integrated ergonomic control handle, the left hand and right hand can easily cooperate, and it is easier to realize convenient assembly. Thick plates and long plates can be easily grabbed, and the steel plate anti-adhesion device can also be selected to facilitate the extraction of ultra-thin steel plates.

Figure 4: The Worker is Operating the Assisted Manipulator

Figure 4: The Worker is Operating the Assisted Manipulator

Summarize

According to the above, the plate loading manipulator is better than manual loading or electric hoist cantilever crane.

Special Note

Both hands control the workpiece positioning at the same time, and the accuracy and operability of the single-handed workpiece positioning are not simply doubling. It is actually quite difficult to operate the workpiece positioning with one hand.

Suppose a small game: two people, one meter apart, each blindfolded, stretch out a finger, and quickly meet the fingertip of the same finger of the other party. Experience it? Many people miss it the first time.

Contrast experiment: Is it easy for the index fingers of a person's two hands to meet quickly one meter away?

Work Process

Figure 5: The Worker is Operating the Assisted Manipulator

Figure 5: The Worker is Operating the Assisted Manipulator

- The forklift will send the steel plate pallet of the specification to be fed to the equipment loading area;

- The operator starts the power-assisted manipulator system from the parking place;

- Position the vacuum suction cup fixture of the power-assisted manipulator at the center of the surface of the steel plate to be picked up for automatic adsorption;

- Slowly lift the workpiece, and continue to lift the workpiece after the load indicator turns red;

- Operate the manipulator to shift, and transfer the steel plate to the equipment workbench;

- Slowly lower the workpiece, and after the load display turns white, press the unload button to unload the workpiece;

- Lift the gripper of the manipulator, move to the parking place, and wait for the next working cycle;

Grab Structure

Vacuum adsorption fixture can quickly grab the workpiece. Each suction cup has a flexible and adaptable device, which can be easily grasped without falling when encountering uneven steel plates. The contact between the claw surface and the workpiece is made of soft materials, which will not cause any bumps. It can realize the gravity-free floating balance of the workpiece, and it will not collide with the lower product when taking and discharging the material. No impact will occur during the start and stop of the lifting action.