Manipulator, also known as power-assisted arm, mechanical arm, balance booster, balance crane, transfer machine, labor-saving spreader, labor-saving gripper, labor-saving handling equipment, etc. It is a gravity-free manual transfer system, It is a novel power-assisting device used for labor-saving operation during material handling. It cleverly uses the force balance and the principle of gas-electric feedback to make the workpiece form a gravity-free floating state in the air, so that the operator cannot feel the weight of the workpiece during the process of transporting the workpiece.

Using the characteristics that the host can balance the gravity of the material, coupled with the grabbing fixture and installation base, we can easily grab the workpiece from one place, implement the corresponding process action, and then place it in another place according to the requirements to achieve labor-saving operation.

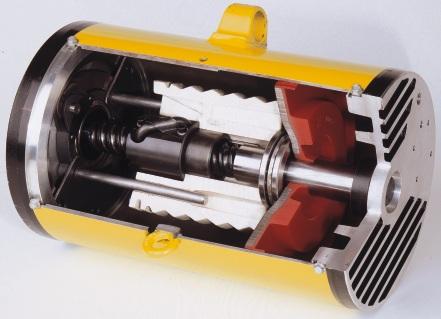

How to achieve this weightless floating state? Take the soft cable pneumatic balancer as an example, let's reveal the mystery:

Pneumatic balancer, using the principle of pneumatics, converts the linear motion of the piston and the winding and rotating motion of the drum to each other through the combination of ball nut/screw, and drives the wire rope to move up and down with small changes in air pressure; with different control systems, it can realize different balance modes to match the corresponding scenarios.

Air Chamber and Piston

The heart of the system. The linear motion of the piston is driven by a slight air pressure change, and the wire rope drum is driven to rotate through the ball nut/screw combination to realize the up and down movement of the load.

Wire Rope Drum

Special engineering plastics that exhibit excellent durability and grinding properties, making every winding motion of the wire rope equally smooth.

Heavy Duty Thrust Bearings

The conversion core of linear motion and winding motion makes the wire rope drum produce smooth rotational motion.

In the state of high-frequency operation, in order to ensure the safety of the operator and equipment, the power-assisted manipulator system needs to be equipped with a number of safety devices.

Load Indicator

The load status can be indicated to inform the operator whether the material can be lifted or unloaded at this time. Improve work efficiency and ensure operational safety.

Misuse Protection Device

Using a unique internal interlocking safety valve group, it can automatically detect the load status and transmit logic signals to the system. The workpiece can only be unloaded after the weight of the workpiece is supported by the worktable, which provides more safety protections for the operator.

Automatic Braking Device

When the up and down running speed is too fast, it will start automatically and lock the up and down of the wire rope.

MOOPEC provide solutions for manipulator systems for manufacturing enterprises and logistics enterprises, emphasizing "people-oriented".