Recently, I had a customer consult me about green aluminum for a Volvo project, specifically discussing the CO2 value of the green aluminum. However, they were not very clear about the definition of green aluminum. I am writing this article to provide a clearer picture of where we currently stand with green aluminum.

1. Background

Low-carbon aluminum, also known as "green aluminum," is increasingly becoming a key topic in the metals market. But what exactly qualifies as low-carbon aluminum, and what are the standards that define it? These questions are crucial, as they lay the foundation for transactions in the market. This article delves into the evaluation standards for low-carbon aluminum from both market and technical perspectives.

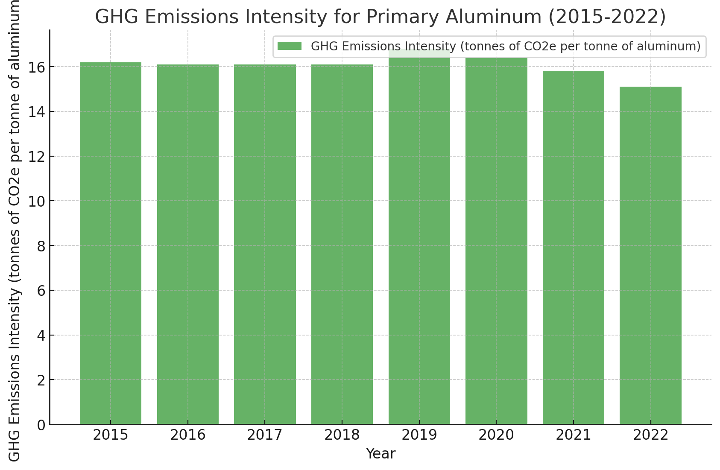

The term "low" in "low-carbon aluminum" is relative. But how low is considered "low," and what about the current levels of carbon emissions or carbon footprint for aluminum? According to the International Aluminum Institute (IAI), the average lifecycle carbon footprint of aluminum was 16-17 tons of CO2 equivalent per ton of aluminum between 2018 and 2021, with 2021 recording an average of 16.6 tons CO2e per ton.

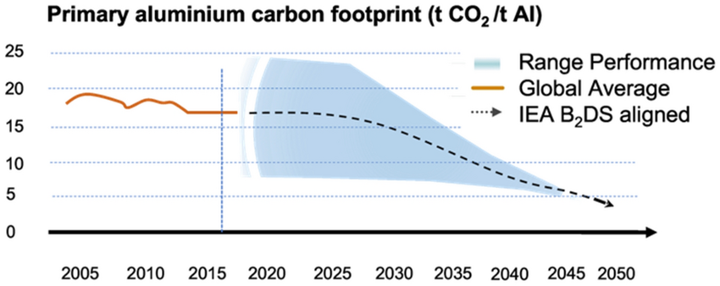

To achieve the goals set by the Paris Climate Agreement for a global temperature rise of less than two degrees, IAI's 2021 report projects that, by 2050, despite an 80% increase in aluminum production, the industry's greenhouse gas emissions need to drop from 1.1 billion tons in 2018 to 250 million tons CO2e—a staggering 77.27% reduction. This calls for concerted efforts across the aluminum sector.

Data from ResearchGate

Given this imperative, the industry is under pressure to lower emissions, particularly from the primary aluminum production process. But how low must emissions go for primary aluminum to be considered "low-carbon"?

2. < 4 Tons CO2 of Aluminum

Carbon emissions from primary aluminum production are influenced heavily by the energy consumed and the technology used. Emission levels vary greatly among producers globally. In April 2020, Carbon Trust suggested that the standard for low-carbon aluminum should be set at less than 4 tons CO2 equivalent per ton of aluminum (4 CO2e/t Al), covering electrolysis, anode production, and ingot casting.

In 2022, the Aluminum Stewardship Initiative (ASI) stated that emissions below 4 CO2e/t Al should reflect a complete lifecycle footprint, including Scope 1, 2, and 3 emissions. While there's no universal definition of low-carbon aluminum yet, the 4 CO2e/t Al benchmark is widely accepted and approaches the lowest emission level achievable with current technology.

3. Market Perspective

Fastmarkets, a leading price reporting and analysis institution, found that most market participants supported the idea of differential trading for aluminum products with carbon footprints below 4 CO2e/t Al. The emissions accounting boundaries include direct smelting emissions and indirect emissions from energy consumption. Some stakeholders prefer different thresholds, such as 0-4 or 4-8 CO2e/t Al, while others argue for a full lifecycle accounting including bauxite mining and alumina refining.

Many aluminum producers have already launched low-carbon brands, such as Hydro's Reduxa 4.0, Rio Tinto's RenewAl, Alcoa's Ecolum and China Aluminum. These brands commonly use a threshold of 4 CO2e/t Al, reflecting broad agreement among producers and their customers.

According to estimates, approximately 68% of aluminum produced outside China has a carbon footprint below 8 CO2e/t Al, compared to 90% in Europe. A study by CRU found that of the 64.33 million tons of primary aluminum produced globally in 2018, around 13 million tons—roughly 20% of the total—had a carbon footprint below 4 CO2e/t Al.

4. Technical Perspective

While global average emissions have remained stable at around 16.1-16.8 t CO2e/t Al from 2015 to 2021, technological advances provide opportunities to reduce emissions further. For example, detailed emission data from Alouette and Hydro shows that reducing emissions from electricity to zero is the most effective way to achieve below 4 CO2e/t Al. With current technologies (excluding inert anode technology), the best achievable emissions total 3.2 CO2e/t Al, providing a feasible path for low-carbon aluminum supply.

5. The Status of Green Aluminum in China

The implementation of the T/CNIA 0168-2022 "Green Electricity Aluminum Evaluation and Trading Guidelines" standard since March 1, 2023, has achieved significant results. Green electricity aluminum products are energy-intensive yet low-emission green products that emphasize the use of green electricity to reduce carbon emissions and environmental impact.

Recycled aluminum, obtained by classifying and reprocessing waste aluminum, offers advantages in resource recycling, energy conservation, and emission reduction. By combining green electricity aluminum with recycled aluminum, it is possible to achieve dual environmental benefits in green, low-carbon aluminum production, namely reducing the carbon footprint and conserving resources.

The Nonferrous Metals Standardization Technical Committee has organized the development of relevant evaluation standards. T/CNIA 0245-2024 "Green Low-Carbon Aluminum Evaluation Guidelines and Traceability Guide" was approved in China on June 27, 2024, and will be officially implemented on September 1, 2024. This is the next evaluation standard for the green, low-carbon properties of aluminum processing products following T/CNIA 0168-2022.

Based on research, the following principles were established for evaluation indicators: firstly, green low-carbon products only specify the usage of raw materials (i.e., green electricity aluminum and recycled aluminum) to control the final product's carbon footprint within a relatively low range without specifying an exact value. Secondly, to ensure that more companies' green low-carbon aluminum products can be identified and evaluated, two levels of green low-carbon aluminum products were set, while strictly screening and limiting the use of non-green raw materials.

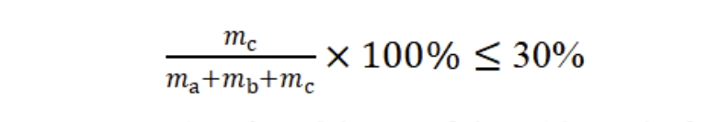

Thus, based on companies' actual production and downstream customer needs, green low-carbon aluminum is categorized into Ultra grade (U-GLA) and Normal grade (N-GLA). Ultra grade refers to products that only contain green electricity aluminum and/or recycled aluminum, while Normal grade includes a small amount of non-green primary aluminum, provided its mass percentage does not exceed 30%. The mass input ratio of recycled aluminum (ma), green electricity aluminum (mb), and non-green primary aluminum (mc) must satisfy ma + mb + mc ≤ 100%, with mc ≤ 30%.

The prefix U-GLA represents "Ultra Green & Low-Carbon Aluminum," indicating Ultra grade green low-carbon aluminum, while N-GLA represents "Normal Green & Low-Carbon Aluminum," indicating Normal grade. The number before the decimal point indicates the mass percentage of recycled aluminum in the input aluminum material (excluding intermediate alloys, additives, and fluxes), and the number after the decimal point indicates the mass percentage of green electricity aluminum.

For example, if recycled aluminum accounts for 42% of the total aluminum material input, and primary aluminum accounts for 58%, of which 80% is green electricity aluminum, the marking for a round aluminum alloy billet that meets YS/T 67 requirements would be: Deformable Aluminum & Aluminum Alloy Round Billet - N-GLA42.46-YS/T67.

If this round billet is used as raw material to produce an aluminum alloy profile for solar cell frames that meets YS/T 773 requirements, the traceability mark would be: Solar Cell Frame Aluminum Alloy Profile - N-GLA42.46-YS/T67-YS/T773.

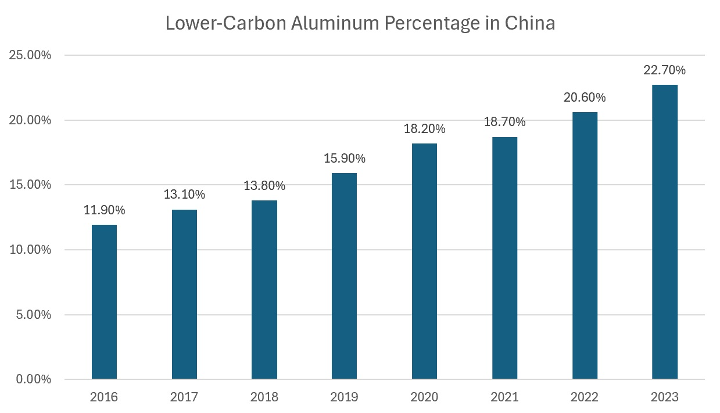

China's low-carbon aluminum production has significantly increased in recent years. According to MOOPEC data, production grew from 3.86 million tons in 2016 to 9.47 million tons in 2023, representing 22.7% of the country's total aluminum output. The shift of production capacity to southwestern China, where hydropower resources are abundant, and the development of green energy have been key factors. In 2024, with the early resumption of Yunnan's aluminum production, low-carbon aluminum's share of total production is expected to continue growing, likely reaching 24%, and potentially achieving 25% by 2025.

6. Conclusion

Low-carbon aluminum is emerging as a crucial component in the global push towards sustainability. With both market demand and technological advances driving lower emissions, the industry is making significant progress. The benchmark of 4 CO2e per ton of aluminum has become a widely accepted standard, indicating a feasible and realistic goal for producers. As countries and companies continue to adopt greener practices and renewable energy, the share of low-carbon aluminum will likely grow, helping the world achieve its ambitious climate targets. The ongoing development of low-carbon aluminum, particularly in China, highlights the potential for more sustainable production practices in the aluminum industry globally.