Grain Oriented Silicon Steel (CRGO) is the go-to material for transformer cores. With a silicon content of 0.8% to 4.8%, this soft magnetic material offers exceptional magnetic permeability, making it a critical component in building efficient magnetic circuits for transformers.

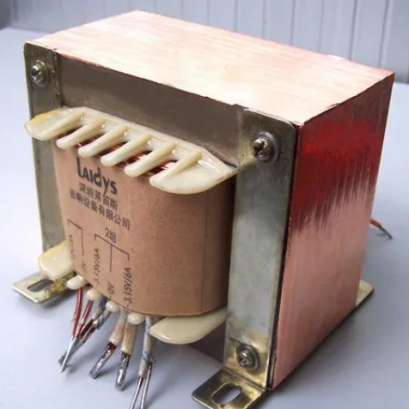

Transformer Core

Transformer Core

Why Use Grain Oriented Silicon Steel in Transformers?

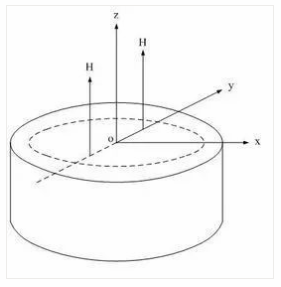

Transformers operate under alternating magnetic fields, which lead to core losses—mainly hysteresis loss and eddy current loss. CRGO features a very narrow hysteresis loop, requiring less energy to magnetize, thus significantly reducing hysteresis loss and unwanted heat generation.

Transformer alternating magnetic field

Transformer alternating magnetic field

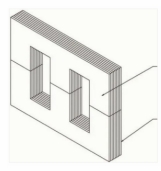

To reduce eddy current loss, transformer cores are built using insulated lamination stacks of CRGO sheets, typically between 0.18mm and 0.30mm thick. This laminated structure increases electrical resistance along eddy current paths, minimizing energy loss. Additionally, CRGO’s naturally high resistivity further suppresses eddy currents.

Core insulation laminated structure

Core insulation laminated structure

Popular Grades and Their Applications

The current mainstream transformer core materials are high-performance cold-rolled grain oriented silicon steels. Common Baosteel grades include:

-

20/065, 20/075, B23R080 – Ideal for high-end transmission transformers

-

B27R095, B30R120 – Widely used in distribution transformers

Internationally recognized grades also dominate the market:

-

Japan (JFE): HI-B® series

-

Germany (ThyssenKrupp): M130-27P

-

USA (AK Steel): AK SURA®

MOOPEC offers expert material selection and customization based on client application needs.

Manufacturing Advancements in CRGO

Unlike earlier hot-rolling processes, today’s transformer-grade CRGO is produced via cold rolling, using a single cold-rolling and double-annealing process. Advanced techniques like decarburization annealing and nitriding treatment are applied to ensure grain alignment, magnetic uniformity, and refined domain structure.

![]() Technological process

Technological process

MOOPEC has the capability to stably supply ultra-thin CRGO sheets in 0.18mm, 0.20mm, and 0.23mm, providing strong performance advantages for high-efficiency, high-frequency transformer designs.

Key Material Properties of High-Quality CRGO

![]() Oriented silicon steel laminated sheets

Oriented silicon steel laminated sheets

-

Low Core Loss: Lower iron loss improves transformer efficiency

-

High Magnetic Induction: Enables compact core design

-

Excellent Lamination Performance: Uniform thickness and flat surfaces enhance assembly quality

-

Stable Insulation Coating: Strong adhesion and high corrosion resistance

-

Superior Magnetic Aging Resistance: Maintains performance over long-term use

-

Good Workability: Suitable for automated high-speed punching and forming

MOOPEC’s Customization and Service Capabilities

Beyond supplying Baosteel CRGO grades, MOOPEC provides a one-stop solution, including:

-

Small batch & multi-spec supply – ideal for new project development

-

Fast prototyping and tooling – samples ready within 72 hours

-

Precision cutting and traceable quality control – from samples to trial production

-

Global delivery with multi-currency transactions – servicing Southeast Asia, Europe, and the Americas

Nominal Thickness(mm) | MOOPEC | Theoretical density (KG/dm³) | Min. Induction(T) | Min.Lamination factor(%) |

| 0.20 | M20G65 | 7.65 | 1.89 | 95.0 |

|

0.20

| M20G70 |

7.65

| 1.89 |

95.0

|

|

0.20

| M20G75 |

7.65

| 1.90 |

95.0

|

|

0.20

| M20G80 |

7.65

| 1.90 |

95.0

|

| 0.23 | M23G75 |

7.65

| 1.89 |

95.5 |

|

0.23

| M23G80 |

7.65

| 1.88 |

95.5

|

|

0.23

| M23G85 |

7.65

| 1.86 |

95.5

|

|

0.23

| M23G90 |

7.65

| 1.90 |

95.5

|

|

0.23

| M23G95 |

7.65

| 1.89 |

95.5

|

|

0.23

| M23G100 |

7.65

| 1.89 |

95.5

|

| 0.27 | M27G90 |

7.65

| 1.90 | 96.0 |

|

0.27

| M27G95 |

7.65

| 1.90 |

96.0

|

|

0.27

| M27G100 |

7.65

| 1.90 |

96.0

|

|

0.27

| M27G105 |

7.65

| 1.89 |

96.0

|

| 0.27 | M27G110 | 7.65 | 1.89 | 96.0 |

| 0.27 | M27G115 | 7.65 | 1.89 | 96.0 |

| 0.27 | M27G120 | 7.65 | 1.88 | 96.0 |

| 0.30 | M30G100 | 7.65 | 1.90 | 96.5 |

| 0.30 | M30G105 | 7.65 | 1.90 | 96.5 |

| 0.30 | M30G110 | 7.65 | 1.89 | 96.5 |

| 0.30 | M30G120 | 7.65 | 1.89 | 96.5 |

Future Trends: Thinner, Greener, More Efficient

Driven by global carbon neutrality goals and green energy growth, energy-efficient, high-induction CRGO materials—like Baosteel’s Hi-B® series—are becoming the industry standard.

Over the next decade, the market will prioritize:

-

Ultra-thin gauges

-

Low-loss performance

-

Eco-friendly manufacturing

-

Consistent magnetic properties

MOOPEC will continue to empower clients with advanced material solutions that balance cost, efficiency, and sustainability, supporting their competitive edge in the evolving energy equipment sector.